Our Philosophy

We are proud to tell you that our philosophy is one of the most controversial and picked on standpoints in the brewing industry. Nevertheless, we at VPB insist that:

""Beer with a lot of flavor is great! But it is also very filling. When you want to drink a lot of beers, at a friendly poker game for example, you should be free to do that, without feeling like you just ate a Thanksgiving dinner. Additionally, many people believe that what makes a beer great, is the absence of flavor.""

Beer brewers can choose to make lagers, or ales, or both. Many microbrewers focus on flavors. And the majority of small brewers produce ales. They often post blogs and rag on lagers or light beers. They make jokes like, "Why brew a beer like that, you can just piss in a cup and get the same thing." But on your next trip to the store you will see that the best selling beers are lagers. Here in Norway they stock pallets full of Tuborg and Carlsberg. In the US, despite all the shit talking about Bud Lite, Miller Lite, and Coors Light, these 3 beers occupy 65% of the shelves. Why? Because the majority of people just want a smooth beer that goes down easy.

I love a good India Pale Ale, but what I prefer is a smooth lager. The dirty little secret, the reason many small brewers make ales, is that they don't have the equipment to ferment beer at 10 degrees celcius. At VPB, thanks to our old spare refrigerator, we can ferment lagers. And,we don't care if the process takes longer.

Who we are

Viking Pirate Brewing is a small outfit with very few employees, located on the outskirts of Oslo. We currently have a relatively small brewing capacity of 50 liters brewed per day. But we don't brew that much because our fermenting capability is much less, approximately 50 liters per 14 days. The batches also require another 14 days of conditioning. Our fermenting capability is limited because we ferment using an old refrigerator, which holds 2 large 25 liter fermenters.

So each batch requires around a month before completion, but the taste is well worth the wait. We can ferment much more when we produce ales, around 300 liters per 17 days, but we rarely produce ales.

Our staff consists of 3 employees, and 4 external consultants. All consultants work on a voluntary basis, because they get to constantly try out the product.

Our Employees

Thomas

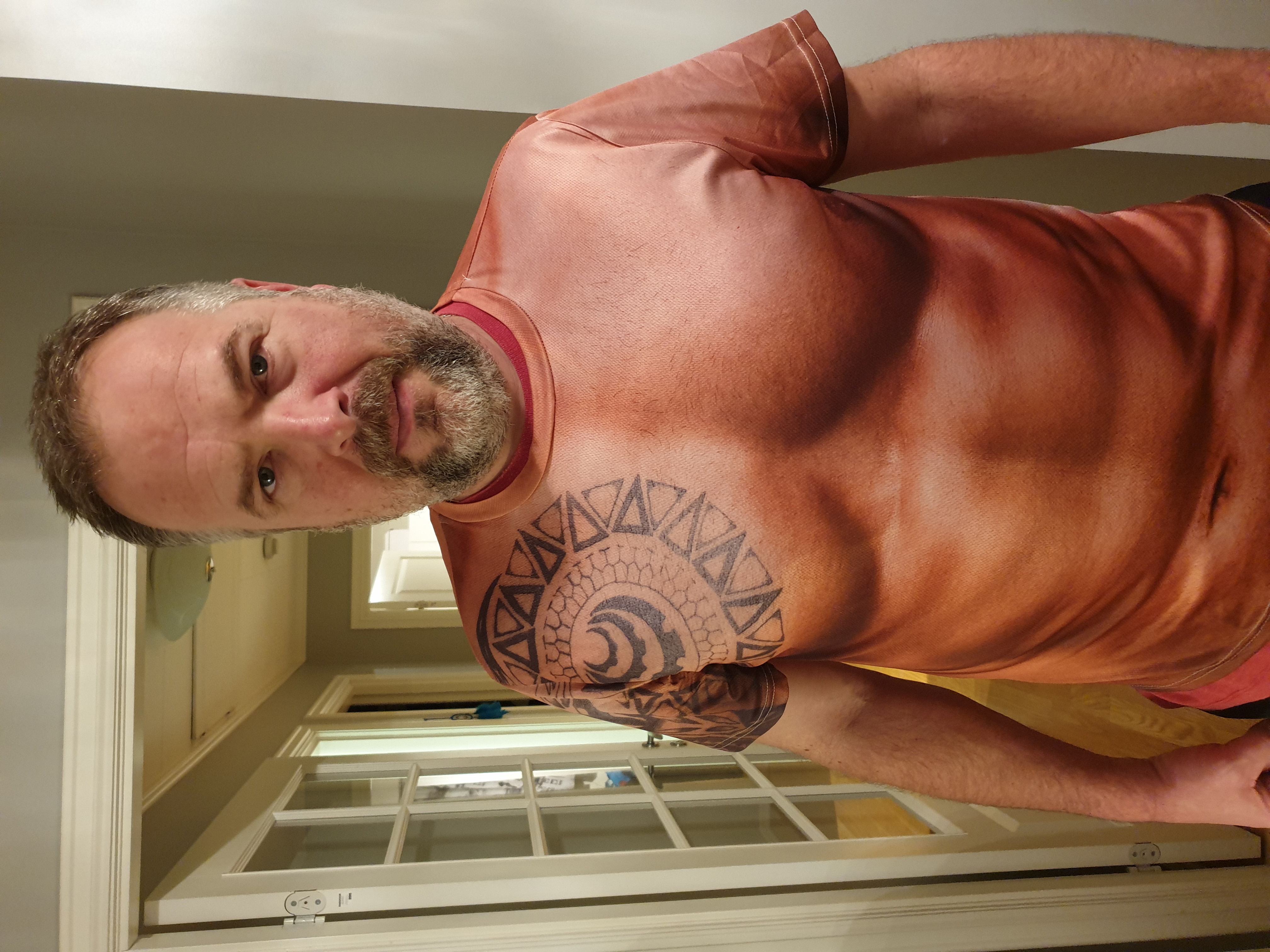

"Daddy"

Godwin

CEO, CIO, CFO, and Head Brewmaster

Lucas

"Skywalker"

Godwin

Bottling Manager

NOTE: My son does not drink alcohol, nor is he encouraged to or allowed to. He just grabbed mine one time because he thought it would make a funny picture!

Ethan

"Big E"

Godwin

Capping Manager

Fermenting Secrets

We have only two secrets to fermenting good beer. The first is that we scientifically deduce the precise amount of yeast cells needed, for the fermenting and conditiong phases to produce the optimum smooth beer. Many microbrewers are so scared that their beer will not ferment, they use 2 to 3 times the amount of yeast they need, which leads to a potpourri of possible off-flavors. We don't, we can count cells.

Our other secret, which is how to speed up the fermenting process for lagers is, well, not a secret, and it's not our secret either. It's all over the internet, and we didn't create it. But it saves us money on our website because we don't have to produce our own video. Here is one example of a good technique:

Contact us

Want a custom 25 or 50 liter batch for yourself, tailored to your tastes? Contact us by email, and we will direct you to fill out our beer taste preference form.